Assumptions. That’s where the problem lies. At least when it comes to engineering design proposals. It’s not the budget, not the timeline…it’s the assumptions.

Specifically, the ones we make about the client.

And honestly, if it’s any consolation, it’s not your fault. When you’ve been in the field long enough, certain things become second nature. You know exactly why one material is better than another, why certain tolerances can’t be ignored, why that “small adjustment” the client suggested would actually require reworking the entire design.

But here’s the thing: your client doesn’t know that.

They don’t see the trade-offs, the calculations, or the dependencies that make a design functional. They don’t understand why one option is safer, more efficient, or longer-lasting. And they definitely don’t know that pushing for cheaper alternatives might cost them twice as much in maintenance down the line.

This is why most engineering design proposals fail before they even get off the ground. They assume that clients “get it.” They assume that what’s obvious to the engineer is obvious to everyone else.

They assume too much.

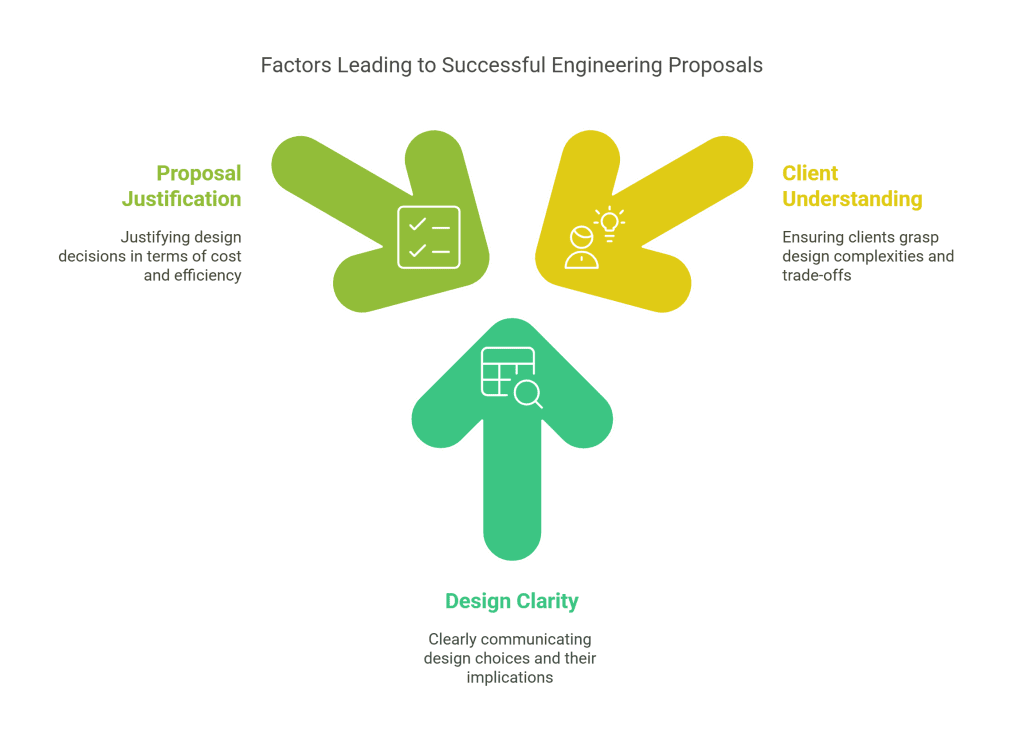

A strong engineering design proposal removes that assumption. It clarifies, justifies, and makes it painfully obvious why the proposed design is the right choice—in terms of cost, efficiency, safety, and longevity. It doesn’t just explain what will be done; it explains why it matters and why no other alternative will work as well.

So, how do you write an engineering design proposal that gets approved quickly, aligns expectations, and eliminates the back-and-forth? Let’s break it down.

Why Most Engineering Design Proposals Fall Apart

1. The Problem Statement is Too Vague

If the client doesn’t fully understand the problem, they won’t fully understand the solution.

Most proposals jump straight to the design phase, skipping over why the project is needed in the first place. But decision-makers don’t approve projects just because they sound good—they approve them because they solve a problem that’s costing them money, efficiency, or compliance.

Instead of saying:

“The existing system is outdated and inefficient.”

Be specific:

- The current filtration system exceeds operational costs by 25% due to outdated components.

- Downtime for maintenance has increased from four days per year to ten, leading to a $500,000 annual revenue loss.

- Upcoming regulatory changes will require compliance by Q3, or the company will face fines of $100,000 per violation.

When the problem is clear, the solution becomes necessary.

2. The Engineering Process is a Black Box

Clients don’t need to know every technical detail, but they do need to know how the project will unfold.

A good engineering design proposal doesn’t just say, “We will design and implement X.” It walks the client through the process step by step, showing them exactly what will happen, when it will happen, and what each phase will accomplish.

Here’s how to structure it:

- Phase 1: Research & Feasibility – Benchmarking, risk analysis, initial calculations.

- Phase 2: Conceptual Design & Simulation – CAD modeling, stress testing, material selection.

- Phase 3: Prototyping & Testing – Manufacturing, performance testing, optimization.

- Phase 4: Final Design & Implementation – Refinements, documentation, execution plan.

This way, the client sees progress at each stage rather than waiting weeks or months for a final report with no visibility in between.

3. Assumed Knowledge Creates Gaps

Clients rarely push back because they disagree. More often, they push back because they don’t fully understand what’s being proposed.

If they’re questioning the cost, timeline, or materials, it’s likely because those choices weren’t explained clearly enough.

This engineering design proposal should break down:

- Why a certain material was chosen over another.

- What risks were factored into the cost estimates.

- How the design aligns with compliance and industry standards.

For example, instead of saying:

“We will use a composite material to reduce weight.”

Say:

“A composite material was selected because it reduces weight by 35%, increases durability by 20%, and lowers long-term maintenance costs by 15% compared to traditional steel structures.”

Now, instead of debating the choice, the client sees the value behind it.

How to Structure an Engineering Design Proposal

A well-structured proposal isn’t just about looking professional—it’s about eliminating doubt and making the approval process easier.

1. Introduction: Set the Context

Start with a short, straightforward explanation of the problem and why this project is necessary.

Example:

The industrial cooling systems currently in use experience an annual efficiency drop of 12% due to outdated heat exchangers. This proposal outlines a redesign that improves heat dissipation by 40%, reducing long-term operational costs and ensuring compliance with ISO thermal efficiency standards.

Now, the reader knows exactly why this matters.

2. Problem Statement: Make the Issue Undeniable

Don’t just state the problem—quantify it, justify it, and create urgency.

A strong problem statement should:

- Define what is wrong.

- Show the consequences of inaction.

- Position the proposed design as the best solution.

3. Design Approach: Break It Down Step by Step

Instead of just listing technical specifications, show how the project will be executed in phases:

- Phase 1: Feasibility & Research – Identifying constraints, analyzing alternatives.

- Phase 2: Conceptual Design & Simulations – Structural analysis, stress testing, computational modeling.

- Phase 3: Prototyping & Testing – Real-world performance evaluation, refining specifications.

- Phase 4: Implementation & Execution – Final design adjustments, deployment plan, risk mitigation.

This helps both technical and non-technical stakeholders follow along without confusion.

4. Compliance & Safety Considerations

Every engineering project must meet industry standards. Listing specific compliance requirements reassures clients that risks and legal obligations have been factored in.

Instead of saying, “This design meets safety regulations,” be specific:

- ISO 9001:2015 for quality management.

- ASME B31.3 for process piping compliance.

- OSHA 1910 safety standards for workplace implementation.

This removes uncertainty and prevents last-minute regulatory pushback.

5. Cost Breakdown: Show Where the Money Goes

Instead of just presenting a single number, break it down into key components:

- Material Costs: $X

- Manufacturing & Fabrication: $X

- Prototyping & Testing: $X

- Regulatory Compliance & Certification: $X

- Contingency Budget: $X

Transparency prevents pricing disputes later on.

6. Project Timeline: Keep Expectations Realistic

A structured timeline prevents misalignment on deadlines and keeps progress measurable. Instead of vague timeframes, outline key phases and their expected duration:

- Research & Feasibility Study: Conduct benchmarking, risk analysis, and constraints identification (4 weeks).

- Conceptual Design & Simulations: Develop CAD models, run stress tests, and conduct computational modeling (6 weeks).

- Prototyping & Testing: Procure materials, manufacture prototype, and conduct real-world performance evaluation (8 weeks).

- Final Design & Implementation: Adjust final specifications, obtain approvals, and plan execution strategy (4 weeks).

Breaking it down like this ensures clients understand the process and can track progress without unnecessary follow-ups.

A great proposal must, at the end of the day, makes the approval process easy.

Instead of closing with, “Let us know what you think,” say:

“This proposal presents a cost-effective solution that improves performance, reduces downtime, and ensures compliance. Once approved, we can begin Phase 1 within two weeks. Please review the attached documents, and let us know if you need any additional details before moving forward.”

No assumptions. No guesswork. Just a clear path to the next step.

This is how you write an engineering design proposal that actually gets approved. Need help with Stage 2. Reach out to us! We’d love to help.